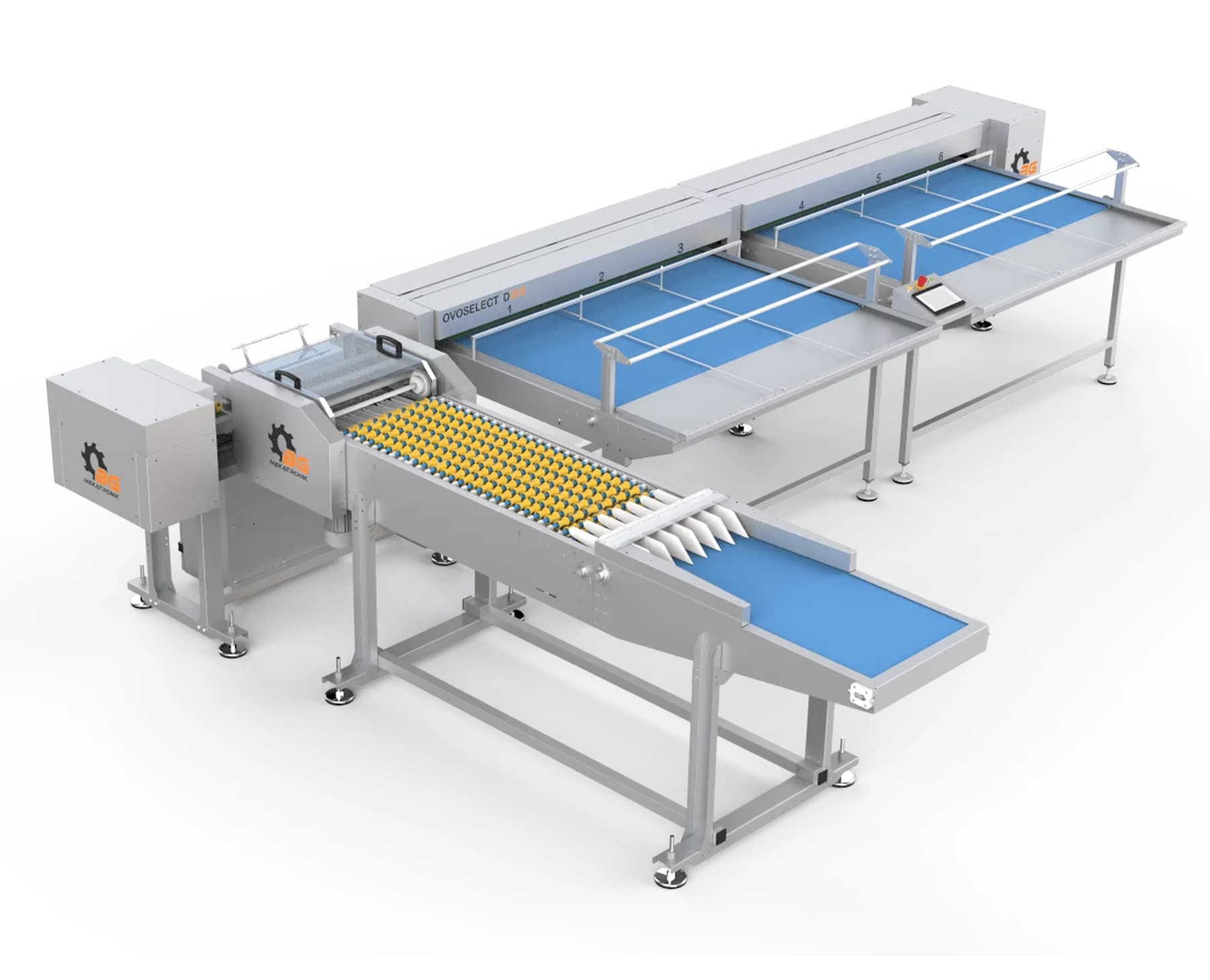

OvoSelect D200 – Medium-sized Egg Grading System

Brochure Download Brochure

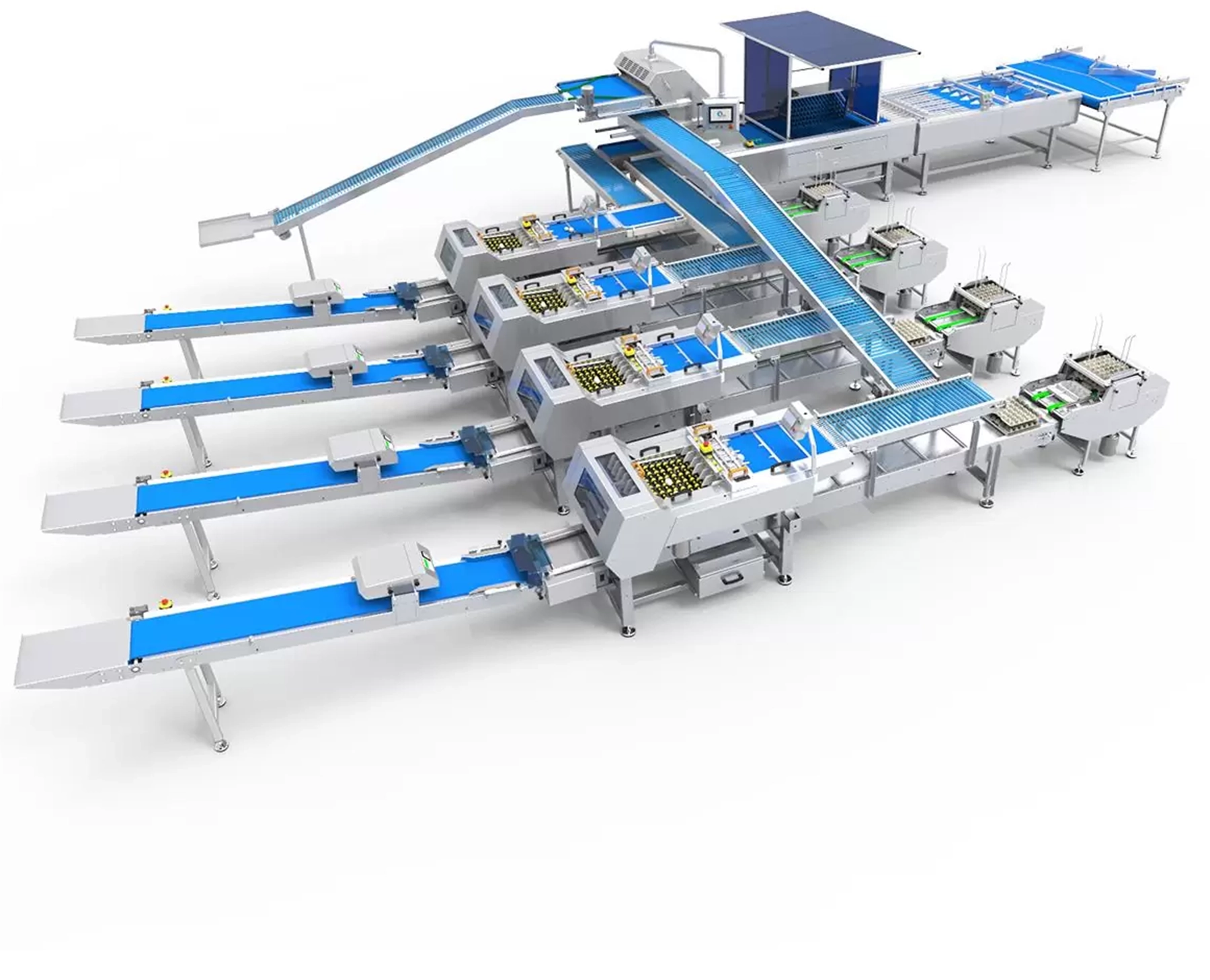

Ovoselect D200 offers the ideal solution for enterprises with an average daily production capacity of 100.000 eggs. The hen house is connected to the egg conveyor and receives eggs with 6 roller inlets. After electronic sorting, it separates them into 6 different groups according to their weight. If desired, a continuous inkjet system can be installed and the eggs can be coded.

Main features of the Ovoselect D200;

- All stainless steel

- High quality and long life electronic weighing system

- Low maintenance cost

- Fast and quality after-sales service

- Retrofittable packaging lines

Egg Printer Installable

With the inkjet printer installed on the sorting, eggs can be sorted and coded in one go.

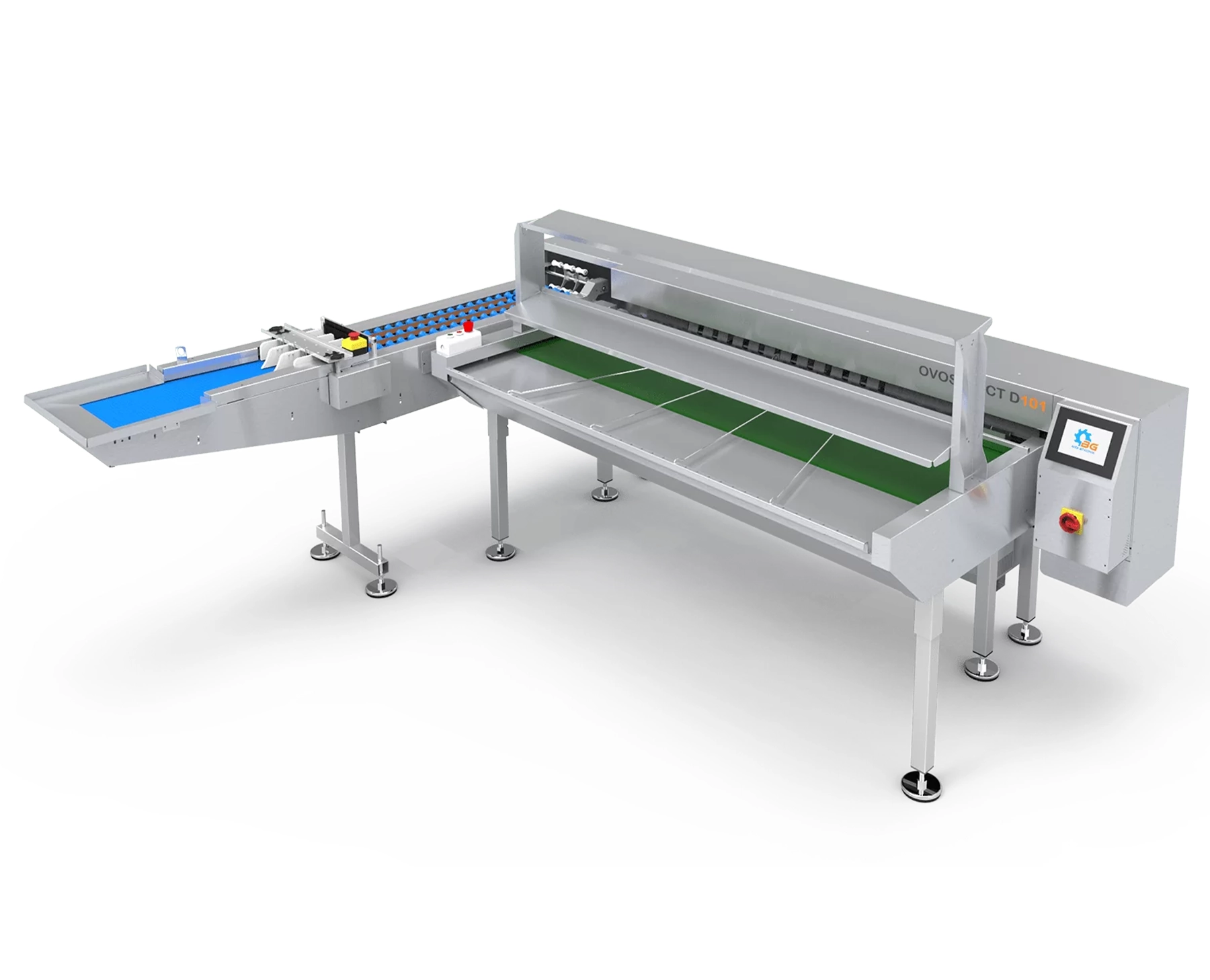

Egg collection table

D200 has a total of 2 egg collection tables with 3 compartments each. Eggs are transported on the tables by plastic rod conveyor. There is also an empty viol shelf.

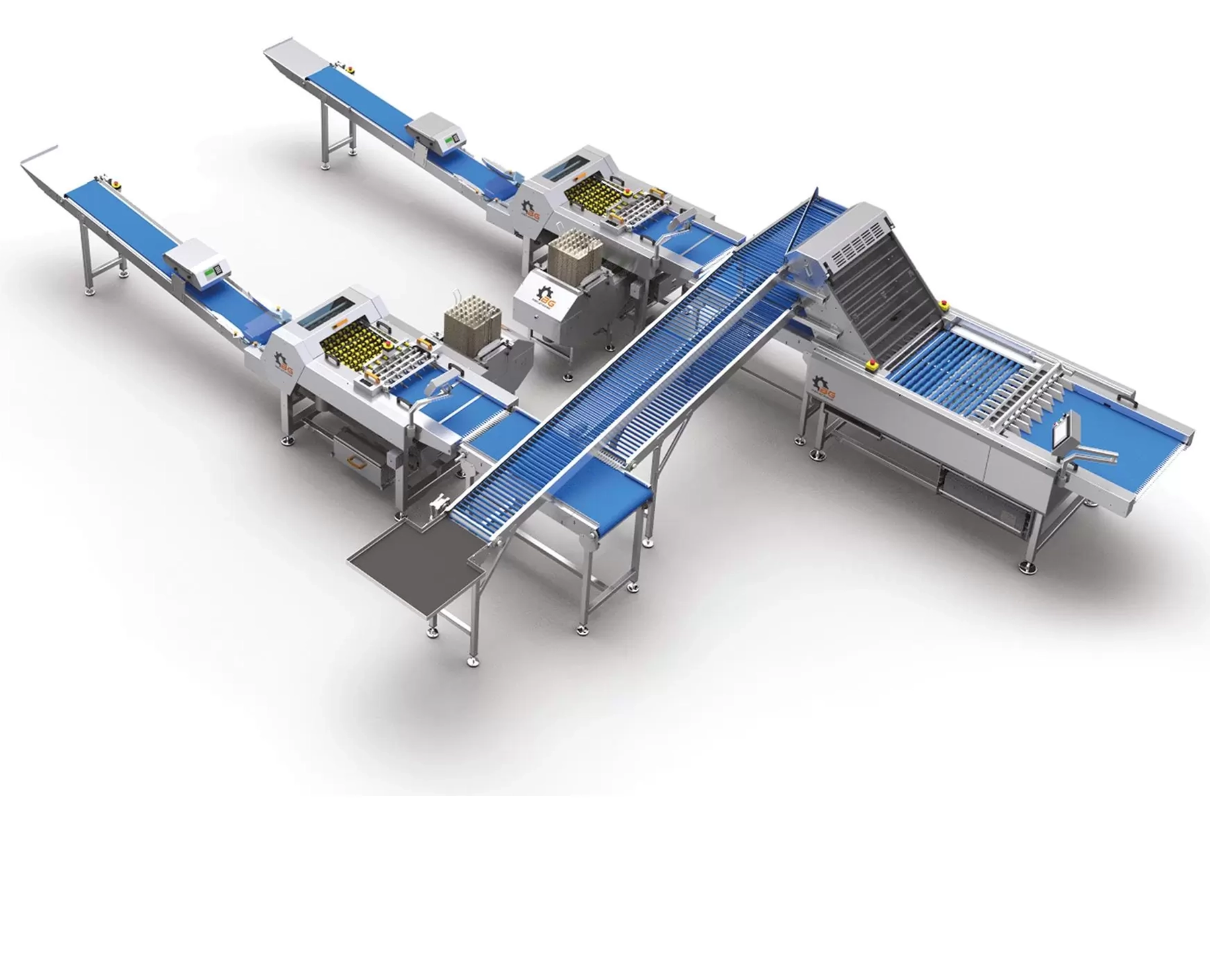

Easily connected to the poultry egg line

The feeding belt of the D200 is designed to allow the entry of eggs from three sides. With a special sensor installed in the system, the eggs are transferred without piling up and breaking.

Antibacterial Cleanable Reels

The egg rollers used in the D200 are made of a special material, which provides the desired flexibility and robustness as well as easy cleaning.

Cracked Egg Control Zone

Thanks to the illuminated egg conveyor of the D200, cracked eggs can be easily identified.

Technical Specifications

| Capacity: | 20,000 eggs/hour |

| Weighing System: | Electronic weighing |

| Weighing Accuracy: | 0,1 gram |

| Classification number: | 6 sizes |

| Operation: | Easy operation with 10″LCD display |

| Analysis: | Egg counts and average weight |

| Power consumption: | 2.3kW three-phase 380VAC |

| Weight(Net/Gross): | 875 kg./ 1000 kg. |

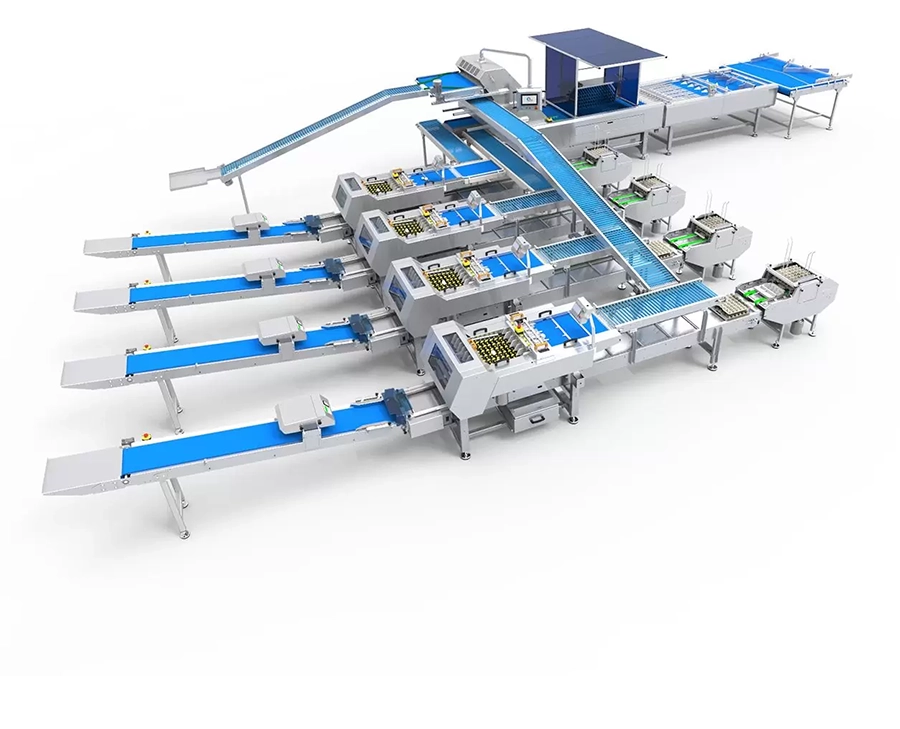

D200 Layout and dimensions